BREATHING AIR COMPRESSOR

Breathing air compressors are used to fill up SCBA and EEBD cylinders. Having the compressor on board determines the minimum number of SCBA cylinders on board as follows:

- If the ship has a BA Compressor, there must be at least 1 charged spare cylinder for each SCBA set for Fire Fighterer Equipment and Safety Equipment.

- If the ship does not have a BA Compressor, there must be at least 2 charged spare cylinder for each SCBA set for Fire Fighterer Equipment and Safety Equipment.

- The source of emnergecy can be from main and energency switchboard or independently driven.

- 60 l/min < BA Compressor filling capacity < 420 l/min or

- self-contained high-pressure storage systems of suitable pressure to recharge the breathing apparatus used on board, with a capacity of at least 1,200 l per required breathing apparatus, not to exceed 50,000 l of free air.'' (50,000 l / 1200 l = 41.7 ≈ 42 max BA cylinders on board if this storage system is being used).

|

| Air flow diagram Source: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/http://www.erpbrandbev.nl/uploads/kcfinder/files/JuniorII-InstructionManual.pdf |

- Air is taken from air intake (1).

- Air is compressed in three stages (3,4,5).

- Between cylinders, there are two intercoolers, one after cooler and one seperator (6,7,8). The intercoolers and after cooler take the heat from the compressed air and let the temperature of the air drops which will increase the compression ratio of the next cylinder. The seperator extracts oil & water.

- The cartridge (filter system) purifies the air compressed air (Hazmat gases such as CO & CO2 are filtered).

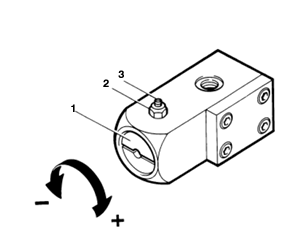

- The purified compressed air comes at pressure maintaining valve. There are two options: 300 bar or 200 bar. One of them would be operational by user choice, which a valve is given. If you turn it clockwise, 300 bar in operation. When you turn it counter-clockwise, 200 bar is operational. The pressure switch over valve should be adjusted only when the compressor is not running and there is no pressure in the system.

|

| Source: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/http://www.erpbrandbev.nl/uploads/kcfinder/files/JuniorII-InstructionManual.pdf |

- It is better to keep 50-80 bar pressure in the system after use to prevent moisture.

- Always keep maintence records up dated.

- Before any maintenace, depressurise the system.

- Loose the nut (2)

- Set screw (1)

- Adjust screw by a screw driver (1)

|

| Source: chrome-extension://efaidnbmnnnibpcajpcglclefindmkaj/http://www.erpbrandbev.nl/uploads/kcfinder/files/JuniorII-InstructionManual.pdf |

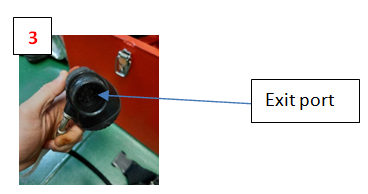

There are three safety valves at all three compression stages. However, what we are interested is the safety valve for third stage or final safety valve because it is mounted above the filer assembly (the other two ones are not visible) and it allows us to adjust final pressure. Actually, that safety valve is intented to be used to blow off pressure the exceesive pressure in case of mulfanctioning but in reality, I have observed that the engineers responsible for BA Compressor maintenace were adjusting final pressure simply by turning the knob at the top of the final safety valve.