FIRE HYDRANTS AND ISOLATION VALVES

Here I will mention the followings;

- The material of valves

- The most common types of fire hydrants & isolation valves on board (globe, butterfly, gate)

- Gate valve lapping

- SOLAS Requirements

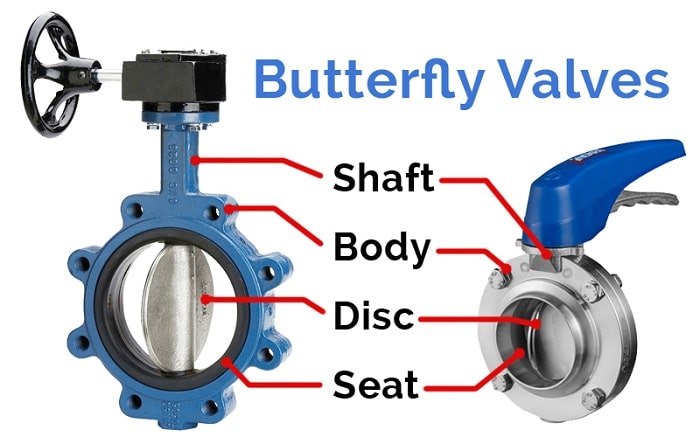

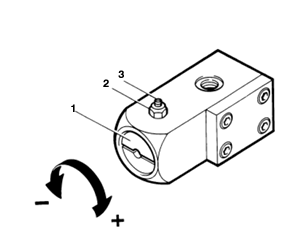

The butterfly valves are commonly used as fire isolation valves. It offers start-stop-regulate flow. Valve is fully open when the disk rotates 90 degrees. The flow is nearly not obscured so that pressure drop is minimal. It is important that the valve should be closed slowly to prevent disk from structural damage and hummering. If there is leakage in the valve, the disk and seat should be examined and cleaned.

- Check if lapping is required or not.

- Isolation valves shall be installed for all open deck fire main branches used for purposes other than fire fighting. In ships where deck cargo may be carried, the positions of the hydrants shall be such that they are always readily accessible and the pipes shall be arranged as far as practicable to avoid risk of damage by such cargo.

- The diameter of the fire main and water service pipes shall be sufficient for the effective distribution of the maximum required discharge from two fire pumps operating simultaneously, except that in the case of cargo ships the diameter need only be sufficient for the discharge of 140 m³/h.

- Isolating valves to separate the section of the fire main within the machinery space containing the main fire pump or pumps from the rest of the fire main shall be fitted in an easily accessible and tenable position outside the machinery spaces. The fire main shall be so arranged that when the isolating valves are shut all the hydrants on the ship, except those in the machinery space referred to above, can be supplied with water by another fire pump or an emergency fire pump. The emergency fire pump, its seawater inlet, and suction and delivery pipes and isolating valves shall be located outside the machinery space. If this arrangement cannot be made, the sea-chest may be fitted in the machinery space if the valve is remotely controlled from a position in the same compartment as the emergency fire pump and the suction pipe is as short as practicable. Short lengths of suction or discharge piping may penetrate the machinery space, provided they are enclosed in a substantial steel casing or are insulated to "A-60" class standards. The pipes shall have substantial wall thickness, but in no case less than 11 mm, and shall be welded except for the flanged connection to the sea inlet valve.

- Relief valves shall be provided in conjunction with fire pumps if the pumps are capable of developing a pressure exceeding the design pressure of the water service pipes, hydrants and hoses. These valves shall be so placed and adjusted as to prevent excessive pressure in any part of the fire main system.

- In tankers, isolation valves shall be fitted in the fire main at the poop front in a protected position and on the tank deck at intervals of not more than 40 m to preserve the integrity of the fire main system in case of fire or explosion.

- The number and position of hydrants shall be such that at least two jets of water not emanating from the same hydrant, one of which shall be from a single length of hose, may reach any part of the ship normally accessible to the passengers or crew while the ship is being navigated and any part of any cargo space when empty, any ro-ro space or any vehicle space in which latter case the two jets shall reach any part of the space, each from a single length of hose. Furthermore, such hydrants shall be positioned near the accesses to the protected spaces.

- the following minimum pressures shall be maintained at all hydrants: